FlexyPlant

Modular Concept Raised to Plant Scale

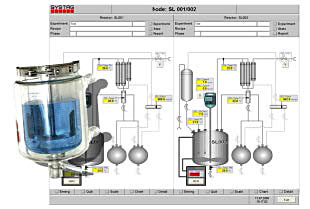

FlexyPlant combines the modular controlled reaction concept that FlexyCUBE and FlexyPAT bring to the laboratory with the flexibility of the FlexySys control system to provide integrated automation of production scale processes.

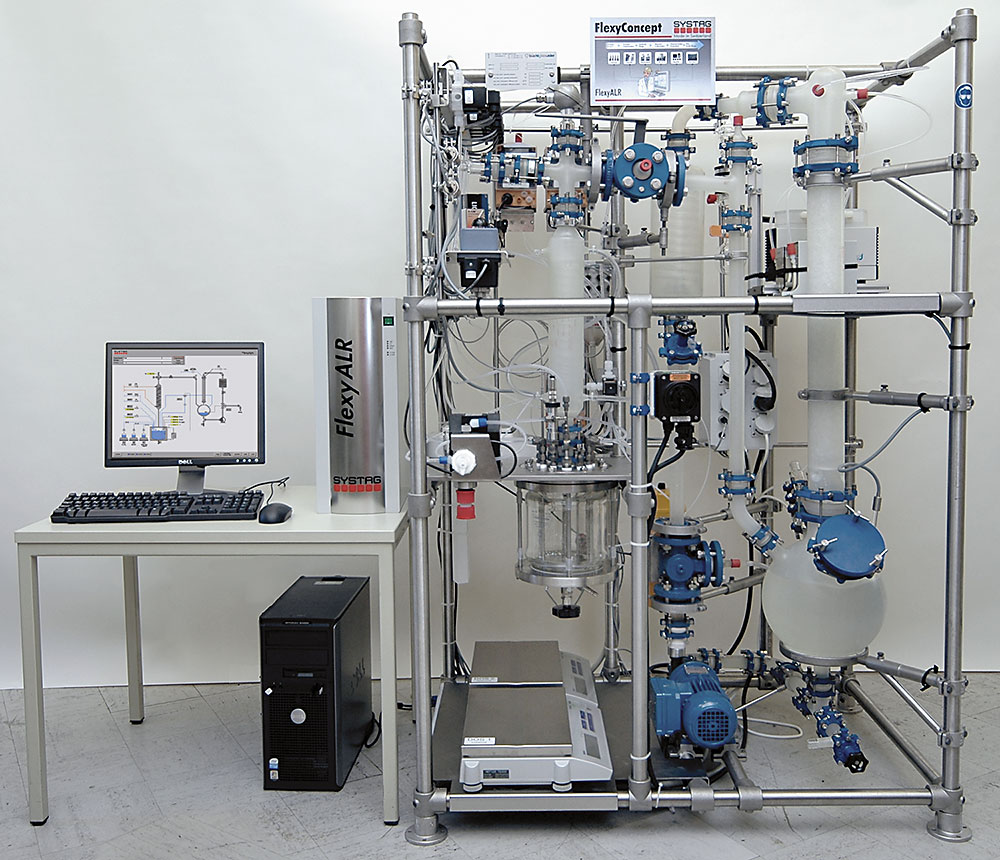

FlexyPlant provides customers with customized design solutions for the complete automation of kilo lab plants with reactor sizes up to 250 liters. These can be provided as design solutions, including functional control software specifications, user interface, control hardware, input/output lists and circuit diagrams.

Alternatively, FlexyPlant can create a total turnkey production plant, complete with reactors, sensors and fittings, in collaboration with Swiss partners Büchi.

FlexyPlant technology is also applicable to pilot plants, special reactors and challenging chemical process technologies such as polymerizations, hydrogenations or thermal separation of substances.

Application

FlexyPlant is SYSTAG’s automation solution to the particular demands imposed by kilo lab and pilot plants, where the quantities of materials used require the process management of a production operation, together with a comprehensive safety concept. At the same time, the operating team must be able to respond quickly and flexibly to any deviation from the defined process.

The provides the final link in a universal control concept that extends from laboratory to pilot plant and production, with consistent look and feel, interchangeable recipes, automatic data acquisition/logging and end-to-end compliance with GMP and CFR 21, Part 11.

It provides centralized control of all special apparatus, including rectification units, hydrogenation autoclaves, and polymerization plants. The FlexySys process control system combines the flexibility of manual operation with the safety, reliability and reproducibility of a recipe-controlled plant.

Implementation

Plant specifications are developed in close co-operation with the user. The customer can contact specialists at SYSTAG with professional understanding of the detailed working practices and requirements of process development. In close co-operation with the customer, SYSTAG will produce a detailed specification that will in turn be used as the basis for a tailored FlexyPlant automation solution or a turnkey production plant.

The requirement specification encompasses functional specifications for control software, a practical user interface, selection of control hardware (e.g. Siemens S7, Beckhoff), I/O lists and switch cabinet planning and cable diagrams.

Turnkey systems also include P&I diagrams, peripheral devices such as pumps, scales, sensors, valves, fittings and core hardware including reactors, structural reactor components, templates and Nutsch-type filters with the latter supplied by respected Swiss partner, Büchi.